Advanced Manufacturing & Engineering Solutions

At Questaero Systems Pvt Ltd (QSPL), we combine precision manufacturing, advanced engineering, and innovative processes to deliver solutions that meet the stringent demands of aerospace, defence, energy, infrastructure, and medical sectors. From prototyping to full-scale production, our capabilities ensure quality, reliability, and scalability across industries.

Our Core Capabilities

Design & Engineering

- 3D CAD modelling for mechanical parts and assemblies

- NC programming for CNC machining

- APQP-driven product and manufacturing process planning

- DFMEA and PFMEA for design and process risk assessment and mitigation

- Rapid prototyping and engineering validation builds

- Qualification testing including environmental and functional testing

- PPAP and First Article Inspection (FAI / AS9102) documentation

- Electrical schematics, wiring diagrams, and interconnection drawings

- PCB design, layout, DFM, and controlled BOM for assembly

- Cable and wire harness design compliant with IPC/WHMA-A-620

- Box build and system-level electro-mechanical design and integration

- Engineering documentation, configuration management, and change control

Precision Machining

- CNC 3-axis, 4-axis, and 5-axis machining for complex geometries

- High-precision turning, milling, and drilling operations

- Titanium, aluminium, stainless steel, copper alloys, and exotic materials

- Jigs, fixtures, gauges, and assembly tooling manufacturing

- Prototyping to production support for aerospace and industrial parts

Sheet Metal Fabrication

- CNC laser cutting, CNC Routing, punching, bending, and forming

- Welding (TIG, MIG, Spot, Orbital) and structural assembly

- Riveting, hemming, and fastener integration

- Cabinets, enclosures, panels, brackets, and structural parts

- Powder coating, painting, and surface treatment

Casting

- Aluminium, steel, and special alloy casting with high dimensional accuracy

- Gravity Die Casting (GDC), Low Pressure Die Casting (LPDC), and High Pressure Die Casting (HPDC)

- Sand casting and investment casting for complex geometries

- Machining, heat treatment, and finishing of cast components

- Small-to-medium batch production for aerospace, automotive, and energy applications

Forging

- Aerospace-grade forged components (Aluminium, Titanium, Alloy Steels)

- Closed-die, open-die, and ring rolling processes

- Heat treatment and non-destructive testing (NDT) for quality assurance

Molding

- Plastic, composite, and rubber molding for lightweight, durable components

- Injection and compression molding processes

- Prototyping for consumer, medical, and electronics applications

- Low-to-medium volume production

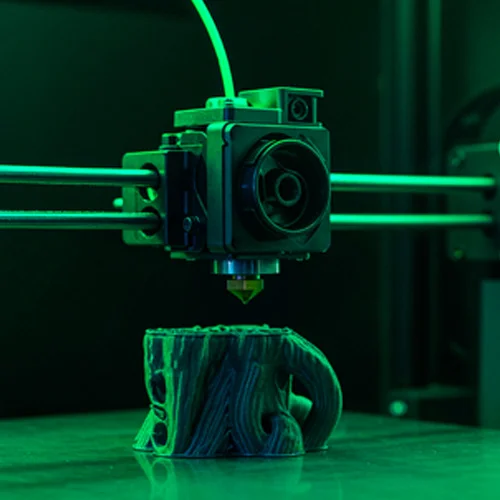

3D Printing / Additive Manufacturing

- Rapid prototyping for design validation

- Low-volume production of functional components

- Polymer, resin, and metal printing capabilities

- Lightweight and topology-optimized parts for aerospace and medical industries

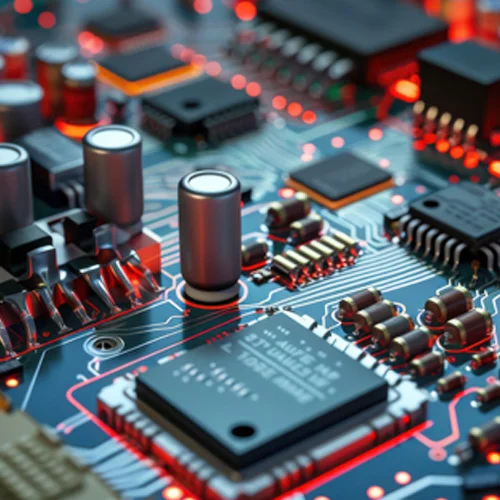

Electronic Component Sourcing & Kitting

- Global procurement of critical electronic components

- Supply chain management and lifecycle support

- PCB assembly support, connectors, and interconnect solutions

- Kitting, logistics, and inventory management

- Value engineering for cost-effective sourcing

Mechanical Assembly

- Sub-assembly and final assembly of precision components

- Integration of machined, sheet metal, cast, and molded parts

- Riveting, fastening, and alignment for high-accuracy builds

- Assembly of housings, enclosures, panels, and mechanical structures

- Functional testing and validation of assembled units

MIL Grade Surface Treatments & Finishing

- Anodizing, plating, and passivation

- Powder coating, painting, and polishing

- Shot peening, deburring, and cleaning for aerospace-grade finish

Cable & Wire Harness Assembly

Core Capabilities

- Build-to-print cable & wire harness assembly

- Point-to-point wiring, complex looms & routed harnesses

- Crimping, soldering & termination

- Coaxial, RF, power & signal cables

- Shielded & high-temperature harnesses

- Braiding, lacing, heat shrink & protective sleeving

- Continuity, insulation resistance & hi-pot testing

Standards & Quality

- IPC/WHMA-A-620 compliant workmanship

- AS9100 / ISO-aligned processes

- Full material & process traceability

PCB Assembly (PCBA)

Core Capabilities

- Through-Hole (THT), Surface Mount (SMT) & mixed technology assembly

- Fine-pitch & high-density PCB assembly

- Prototype, low-volume & production builds

- Leaded & RoHS-compliant assemblies

- Functional testing & inspection support

Standards & Quality

- IPC-A-610 Class 2 / Class 3 assembly

- Component traceability & lot control

- Incoming, in-process & final inspection

Electro-Mechanical Assembly

Core Capabilities

- Box build & system integration

- PCB, cable & wire harness integration

- Assembly of CNC machined & sheet-metal parts

- Torque-controlled fastening & alignment

- Labeling, marking & configuration control

- Functional & integration testing

Standards & Quality

- Build-to-print with controlled BOMs

- AS9100-compliant documentation

- Complete build records & traceability